Quadrotor Drone - UCLA ENGR 96: Drones

What?

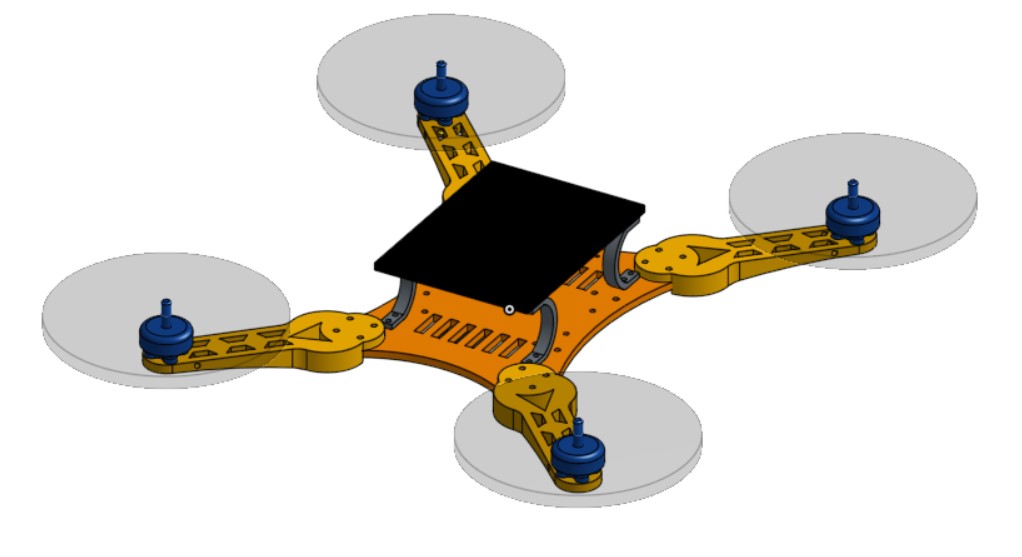

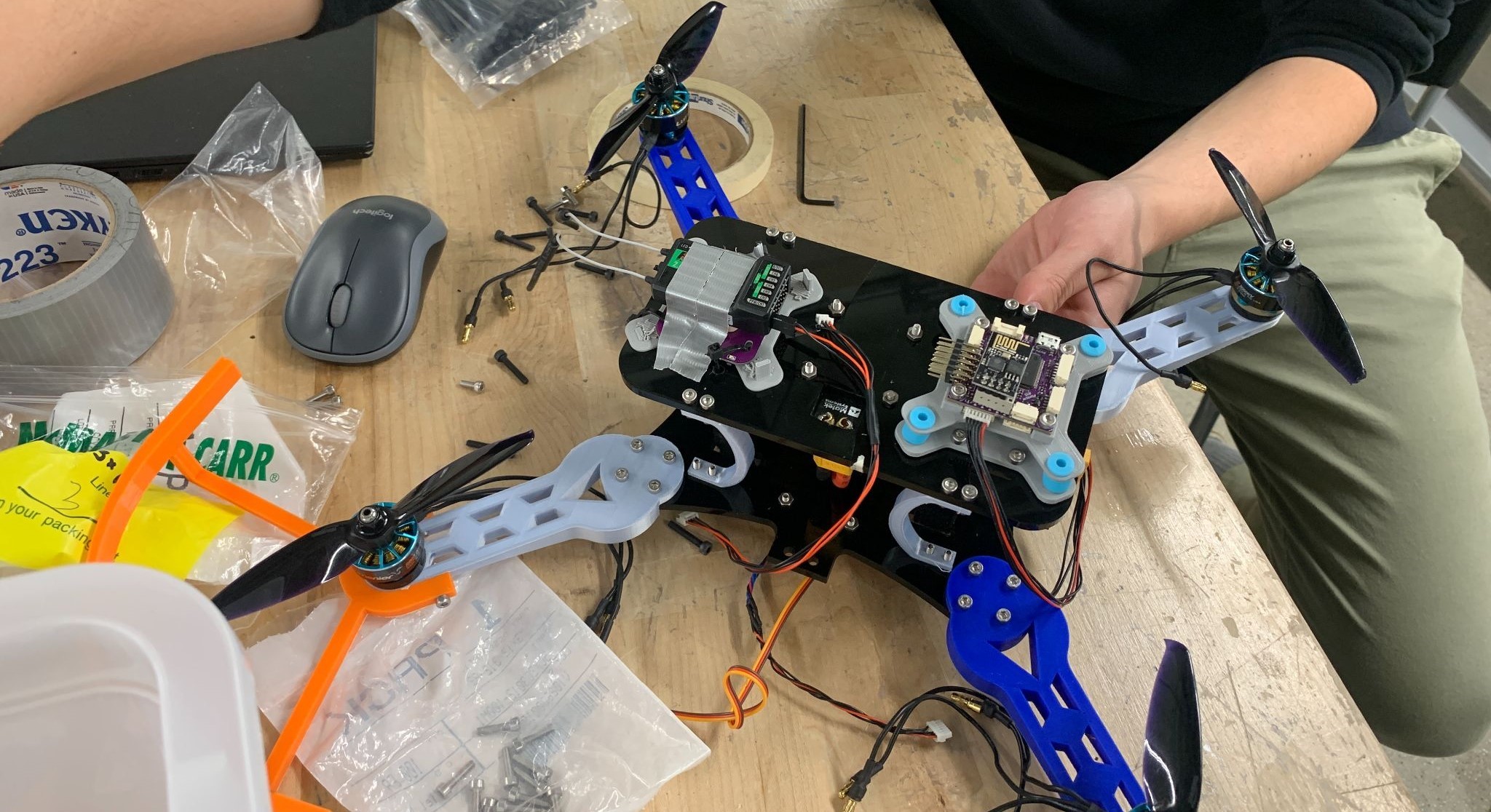

For the drones-focused Engineering 96 class at UCLA, a team of three others and I designed, built, and flew a quadrotor drone. Apart from off-the-shelf electronics, the drone had to be fabricated using only materials and manufacturing techniques available at the UCLA makerspace. At the end of the course, the completed drones had to complete a pre-set course and drop a softball payload in a specified location.

How?

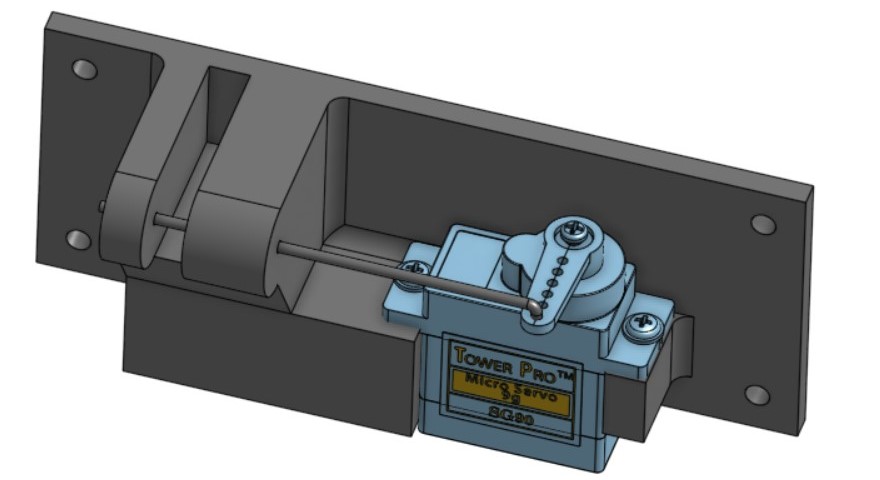

As a mechanical designer on the team, I used Onshape to design the drone's main chassis, arms, and payload release mechanism. The chassis was laser cut from acrylic, and the remaining drone components were FDM 3D printed. All drone components were joined with sockethead screws.

Results

The completed drone flew well -- it felt nimble and maneuverable despite the heavy acrylic chassis, and could navigate the course easily. The payload release mechanism also worked without issue, and the payload could be dropped wherever we wanted. Unfortunately, no amount of careful engineering could compensate for operator error, and a high-speed crash into the ground proved to be too much for our drone to handle.